image

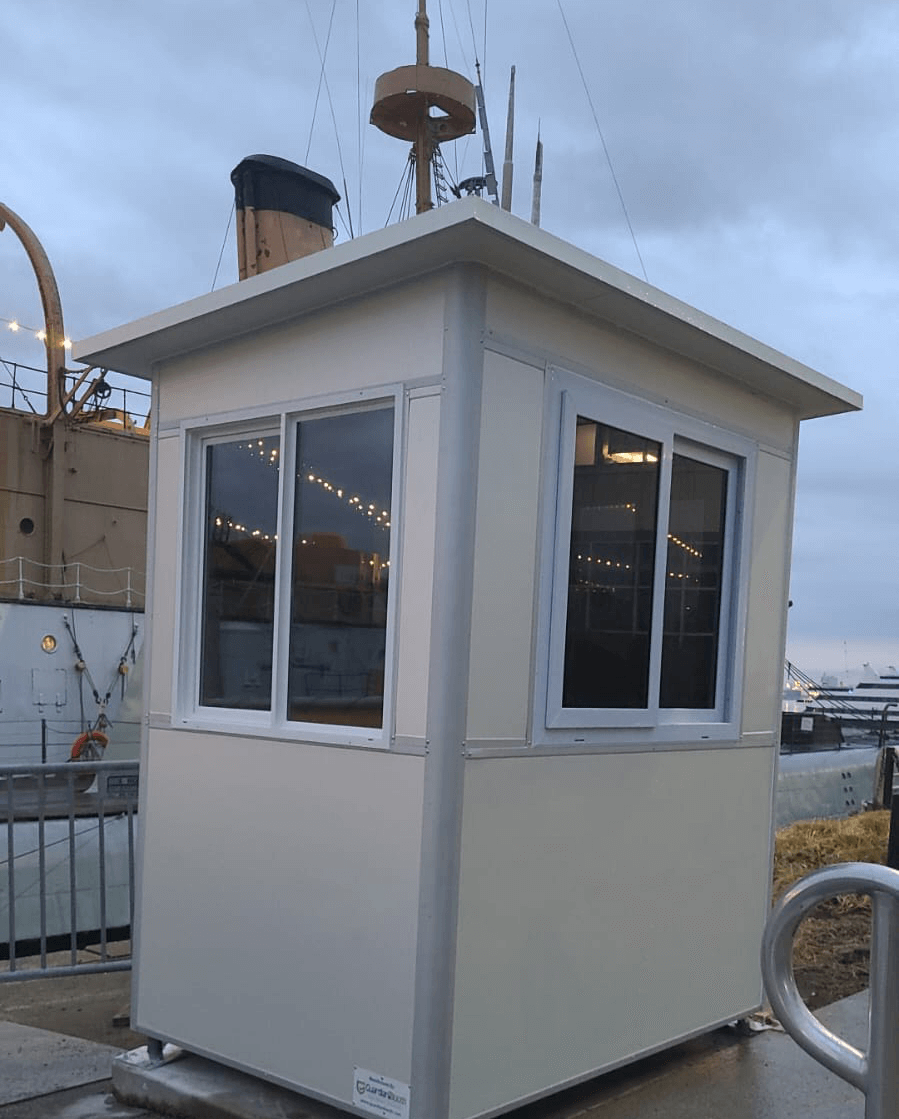

Enhancing Shipping Port Management: The Role of Modular Control and Inspection Booths

In the bustling world of maritime logistics, efficient port management is the linchpin of success. Picture a sprawling shipping port with cargo containers stacked high, a symphony of cranes in motion, and ships arriving and departing at all hours. Amidst this organized chaos, modular control booths and inspection booths have emerged as lifelines for port managers.

These modular structures offer a dynamic and adaptable solution to the logistical puzzle that is global shipping. They provide the flexibility to optimize resources, manage cargo movements, and ensure security. As a shipyard or portyard manager, this scene likely resonates with your daily challenges. These modular solutions enhance efficiency, supporting modern port management strategies and ensuring that every piece of cargo moves seamlessly through your bustling port.

Below, you can explore how modular control booths (monitoring and managing processes) and inspection booths (examining goods and ensuring quality) can elevate and revolutionize your shipping port management.

The Importance of Control Booths in Shipping Port Management

Control booths are the linchpin of efficient shipping port management, offering unmatched security, control, and operational streamlining capabilities. They serve as command centers, fortifying port security, optimizing resource allocation, and expediting entry procedures, ensuring the seamless flow of goods and vessels in this critical nexus of global trade.

Now, let’s take a closer look at the significance of these modular control and inspection booths.

Enhancing Security and Control with Control Booths

Control booths are vital in enhancing control and security in shipping ports. Here are some key ways control booths enhance control and security in shipping ports:

- Surveillance and Monitoring: Control booths are equipped with advanced surveillance systems, including CCTV cameras, radar systems, and other sensors. These tools enable port operators to monitor the movement of vessels, cargo, and personnel within the port 24/7.

- Access Control: Control booths have access control systems such as security gates, card readers, and biometric scanners. This tight access control ensures that only authorized personnel and vehicles enter the port premises, preventing unauthorized access and potential security breaches.

- Communication Hub: With advanced communication systems, including radios and intercoms, control booths can communicate with various stakeholders, including vessel captains, customs officials, and law enforcement agencies. Effective communication is crucial for coordinating port activities and responding quickly to security threats.

- Emergency Response: In emergencies, such as accidents, fires, or security breaches, control booths are central in coordinating rapid responses. They can immediately contact relevant emergency services and deploy resources to the affected areas, minimizing potential damage and hazards.

- Cargo Tracking: The control booth is often a hub for tracking and managing cargo movements. Advanced software systems enable operators to monitor the status and location of individual containers, making it easier to detect anomalies or discrepancies in cargo handling, which could indicate security threats or theft.

- Environmental Monitoring: Control booths are also essential for monitoring environmental factors within the port, such as weather conditions, air quality, and water quality. This data can be crucial for ensuring safe operations and responding to environmental incidents that may impact port security.

- Security Alarms and Alerts: Control booths are equipped with alarm systems that can be activated in case of security breaches or suspicious activities. These alarms can trigger immediate responses, such as lockdown procedures, notifying security personnel, and alerting law enforcement agencies.

A control booth serves as the central nervous system of shipping ports, providing a crucial infrastructure for monitoring, controlling, and securing port operations. Their integrated systems, communication capabilities, and constant vigilance contribute significantly to the overall safety and efficiency of the port, making them an indispensable component of modern port security and management.

Streamlining Entry Booth Operations and Processes in Shipping Ports

Here’s where to position an entry booth and how it would function to streamline processes for boats entering and exiting the water:

Entry Booth Location

The ideal location for the entry booth should be near the waterfront and adjacent to the main boat launch area within the port yard. Here’s why:

- Proximity to Water: Positioning the booth near the waterfront ensures that it’s near where boats are launched and retrieved. This minimizes the distance boats need to travel within the port yard, reducing transit time and congestion.

- Centralized Control: Placing the booth near the main boat launch area allows centralized control and monitoring of all boat-related activities. This is critical for efficient management and oversight.

Functions of the Entry Booth

The entry booth will serve as a hub for all boat-related operations, and its functions will include:

- Access Control: All boats entering and exiting the water will be required to pass through the entry booth. This primary access point ensures that each boat undergoes the necessary checks.

- Documentation Verification: Port personnel stationed within the booth will verify and cross-check all relevant documentation. This includes boat registration, cargo manifests, safety certifications, and required permits. Any discrepancies or missing documents can be addressed promptly, preventing delays downstream.

- Security Screening: The entry booth will have advanced security measures, including surveillance cameras, license plate recognition systems, and possibly biometric access control. These measures ensure that only authorized boats and personnel gain access to the water, enhancing overall security.

- Communication Hub: The booth will facilitate real-time communication between entry personnel and the port’s operational team. Any concerns, discrepancies, or security issues can be reported and acted upon immediately.

- Queue Management: The booth will play a crucial role in managing the flow of boats. A more organized queuing system can be established by controlling access at this point. This reduces congestion, optimizes resource allocation, and minimizes the risk of accidents or delays.

- Data Recording: Detailed records of all boat entry and exit procedures will be maintained, creating a comprehensive database. This data is valuable for compliance, reporting, and security investigations.

- Real-time Monitoring: The booth will have surveillance systems, providing continuous video feeds of boat activities. This enables constant monitoring of operations and the ability to respond promptly to any irregularities or incidents.

By strategically placing the entry booth near the waterfront and implementing these functions, we can streamline the processes for boats entering and exiting the water. This will improve efficiency, reduce congestion, enhance security, and better regulatory compliance within the port.

The Role of Inspection Booths in Shipping Port Management

Inspection booths are pivotal in shipping port management, ensuring adherence to regulations and maintaining industry standards. They serve as critical checkpoints for verifying cargo and vessel compliance, upholding port integrity.

Let’s dive into a comprehensive exploration of the expansive array of achievements these booths can accomplish:

Ensuring Compliance and Safety with Inspection Booths

Inspection booths play a critical role in ensuring compliance and safety in shipping ports. Here’s how inspection booths contribute to compliance and safety in shipping ports:

Safety Concerns Addressed by Inspection Booths:

- Hazardous Materials Handling: Inspection booths help ensure the safe handling of hazardous materials by conducting thorough inspections and verifying that proper labeling, storage, and handling procedures are followed. This mitigates the risk of accidents and environmental contamination.

- Security Checks: Inspection booths contribute to the port’s security by screening for unauthorized personnel, contraband, and potentially dangerous cargo. They help prevent the infiltration of malicious actors and illegal activities within the port.

- Fire and Safety Regulations: Inspection booths can verify compliance with fire and safety regulations by ensuring that cargo is stored and handled following safety protocols. This reduces the risk of fires, explosions, and other safety hazards.

- Cargo Weight and Stability: Ensuring cargo loads are properly secured and distributed within vessels is essential for stability and safety. Inspection booths can check for adherence to weight limits and securement requirements, reducing the risk of capsizing or cargo shifting during transport.

- Health and Environmental Concerns: An inspection booth may monitor cargo for compliance with health and environmental regulations, ensuring no hazardous materials leak or contaminate the environment. They help maintain the overall well-being of port workers and surrounding communities.

- Customs and Import Regulations: Compliance with customs and import regulations is vital for international trade. Inspection booths verify that the necessary customs paperwork is in order and that tariffs and duties are correctly applied.

- Crew Documentation and Safety: The inspection process may include checking the documentation of crew members, such as visas, work permits, and qualifications. Ensuring crews are properly documented and meet safety standards is crucial for maritime operations.

- Security Protocols: Inspection booths often serve as the first line of defense in implementing and enforcing port security protocols. They help prevent security breaches and unauthorized access.

Compliance Requirements in Place:

Compliance requirements in shipping ports are established to ensure the safety of personnel, vessels, and cargo, as well as to uphold international trade regulations. These requirements can include:

- International Maritime Organization (IMO) Regulations: IMO sets global standards for safety and security in the shipping industry. Ports must comply with these regulations, which cover aspects like vessel construction, navigation, and environmental protection.

- Customs and Import/Export Regulations: Ports must adhere to national and international customs regulations to facilitate the smooth flow of goods and revenue collection.

- Hazardous Materials Regulations: Compliance with regulations governing the transportation and handling of hazardous materials is crucial for safety. These requirements often include proper labeling, storage, and emergency response procedures.

- Security Regulations: Ports must implement security protocols to safeguard against terrorism, piracy, and other threats. Compliance involves access control, security screenings, and reporting protocols.

- Environmental Regulations: Environmental regulations dictate how ports handle and dispose of waste materials, manage ballast water, and reduce emissions. Compliance is necessary to protect the environment and prevent pollution.

- Labor and Safety Regulations: Labor laws and safety regulations ensure the well-being of port workers. Compliance includes providing safe working conditions and following labor standards.

Inspection booths are a critical control point to ensure compliance and safety within shipping ports. By addressing various safety concerns and verifying compliance with international and national regulations, these booths contribute to the smooth and secure operation of ports, which, in turn, fosters the reliability and sustainability of global trade.

Efficient Inspection and Documentation Processes

An inspection booth in a shipping port facilitates efficient inspection and documentation processes. Here’s how it achieves this:

- Centralized Inspection Point: An inspection booth is a centralized location for all inspection activities, whether for cargo, vehicles, or personnel. This centralization streamlines the process by ensuring everything is inspected at a single, controlled point, reducing the need for multiple inspections scattered throughout the port.

- Document Verification: One of the primary functions of an inspection booth is to verify and document all necessary paperwork. This includes cargo manifests, customs documentation, permits, and safety certificates. Port personnel within the booth can swiftly check the completeness and accuracy of these documents, ensuring compliance and preventing delays down the line.

- Inspection Protocols: Inspection booths have dedicated facilities and tools for conducting thorough inspections. For instance, they may have scanners for examining cargo contents, scales for measuring weight, and equipment for checking safety standards. All inspections are conducted efficiently within the booth to uphold safety and regulatory requirements.

- Technology Integration: Modern inspection booths are often equipped with advanced technology, including scanners, sensors, and cameras. These tools speed up the inspection process by allowing for rapid data capture and analysis. For example, X-ray scanners can quickly reveal the contents of cargo containers, reducing the need for manual inspections.

- Real-time Communication: Inspection booths are typically equipped with communication systems allowing real-time communication with various stakeholders, including port management, customs authorities, and safety officers. This enables prompt decision-making and issue resolution, ensuring an efficient inspection process.

- Queue Management: To avoid congestion and maintain a smooth traffic flow within the port, inspection booths often implement queue management systems. They control the order in which vehicles, cargo, or personnel are inspected, preventing bottlenecks and optimizing the use of resources.

- Data Recording and Reporting: Every step of the inspection process is meticulously documented within the booth. This includes details of the inspection, any findings, and corrective actions taken if needed. These records are critical for compliance, reporting, and future reference, contributing to efficient documentation.

- Compliance Checks: The inspection booth is a critical checkpoint for ensuring that all cargo and vessels meet safety, security, and environmental compliance requirements. Any violations or discrepancies can be addressed immediately, avoiding potential penalties or operational disruptions.

- Security Screening: Besides compliance checks, inspection booths are pivotal in security screening. They help identify unauthorized personnel or cargo that may pose security risks. This is essential for safeguarding the port and the surrounding area.

By facilitating centralized, systematic, and technology-enhanced inspection and documentation processes, inspection booths contribute to shipping ports’ smooth, secure, and efficient operation. They help maintain compliance with regulations and streamline the movement of goods and personnel, reducing potential bottlenecks and delays.

Features and Customization Options for Modular Control and Inspection Booths

Modular control and inspection booths offer various features and customization options tailored to meet specific port needs. These customizable structures ensure that shipping ports can adapt and optimize their operations, providing a secure and efficient environment for global trade management.

Let’s discuss customization options, including secure access points, advanced monitoring systems, ergonomic layouts, and flexible interior configurations.

Secure Access Points and Monitoring Systems

When customizing modular control and inspection booths for secure access points and monitoring systems, various options are available to enhance security, efficiency, and functionality. These options can be tailored to meet the specific needs of different industries and operational requirements. Here are some key options to consider:

Access Control Systems

Customized control booths can be equipped with access control systems that enhance security. Options include:

- Biometric Scanners: Implement fingerprint, retina, or facial recognition systems to ensure only authorized personnel gain access.

- Access Card Readers: Use electronic access cards or key fobs for controlled entry and exit.

- Keypad Entry: Implement secure keypad entry systems with unique PINs for authorized personnel.

Surveillance and Monitoring Equipment

To enhance monitoring capabilities, consider incorporating advanced surveillance equipment:

- Surveillance Cameras: Install high-definition cameras for real-time monitoring and recording of activities in and around the booth.

- License Plate Recognition (LPR): Implement LPR systems to identify and track vehicles entering and exiting the area.

- Intrusion Detection: Utilize motion sensors and alarms to detect unauthorized access or tampering.

Communication Systems

Efficient communication is crucial for coordination and security. Customization options include:

- Two-Way Radios: Equip booth personnel with two-way radios to facilitate real-time communication with other stakeholders.

- Intercoms: Install intercom systems for immediate communication between booth operators and individuals outside the booth.

- Integrated Communication Networks: Connect the booth to an integrated communication network for seamless interaction with other parts of the facility.

Secure Windows and Doors

Enhance security with customized windows and doors:

- Bullet-Resistant Glass: Use bullet-resistant or ballistic glass to protect booth operators from potential threats.

- Reinforced Doors: Install sturdy and secure doors, possibly with electronic locking mechanisms for added security.

Data and Utility Connections

Customization can include connections for data, power, and utilities:

- Data Connectivity: Ensure the booth can connect to the internet, internal networks, and power sources.

- Electrical Connections: Customize electrical systems for power needs, lighting, and equipment.

- Water and Sanitation: Consider including water and sanitation connections if applicable to the booth’s function.

Emergency and Safety Features

For additional safety measures, you can include:

- Emergency Lighting: Install emergency lighting systems for use during power outages or emergencies.

- Fire Suppression Systems: Customize booths with fire suppression equipment, such as sprinklers or extinguishers.

- First Aid and Safety Equipment: Provide essential safety equipment like kits, fire blankets, and safety signs.

These customization options can be combined and tailored to the specific needs of the site, industry, and the intended functions of the control and inspection booth.

Ergonomic Layout and Design for Operator Comfort

Customizing a control or inspection booth with an ergonomic layout and design is essential for ensuring operator comfort and efficiency. A comfortable, well-designed workspace can enhance productivity, reduce operator fatigue, and promote well-being. Here’s how a port manager can achieve this:

Consider Workflow and Functionality

Before customizing the booth, assess the workflow and specific functions that operators will perform. The layout should support a logical and efficient sequence of tasks. For instance, if the booth is used for cargo inspection, ensure adequate space for inspecting and documenting items.

Choose Appropriate Furnishings

Select ergonomic furniture and equipment to outfit the booth. This includes:

- Ergonomic Chairs: Invest in chairs that provide proper lumbar support, are adjustable in height, and have cushioned seats for long hours of sitting.

- Height-Adjustable Desks: Consider height-adjustable desks that allow operators to switch between sitting and standing positions.

- Monitor Mounts: Use adjustable monitor mounts to position eye-level screens to reduce neck strain.

- Task Lighting: Provide adjustable lighting fixtures to reduce glare and ensure adequate lighting for reading documents.

Optimize Workspace Layout

Arrange equipment and furnishings to minimize unnecessary movement and strain. Key considerations include:

- Proximity to Equipment: Ensure that necessary equipment and tools are within easy reach of the operator’s workstation.

- Workspace Organization: Implement an organized and clutter-free layout using shelves, storage cabinets, and cable management solutions.

- Adequate Work Surfaces: Ensure enough workspace for documents and equipment without overcrowding.

Proper Keyboard, Monitor, and Mouse Placement

When operators are required to use computers, ensure that:

- Keyboards and mouses are positioned at the correct height to prevent wrist and arm strain.

- Mouse pads with cushioned wrist rests are provided to reduce pressure on the wrist.

- Position monitors at eye level and ensures they are at the proper distance from the operator. This reduces neck strain and eye fatigue. If multiple monitors are used, arrange them to minimize head movement.

Acoustic Comfort

Consider noise levels in and around the booth. Use acoustic panels or materials to reduce noise and provide a quieter work environment. Noise-canceling headphones can be offered if needed.

Climate Control

Ensure the booth has an efficient HVAC system that maintains a comfortable temperature and humidity level. Proper climate control contributes significantly to operator comfort.

By customizing a control or inspection booth with these ergonomic considerations in mind, a port manager can create a workspace that promotes operator comfort and well-being. This, in turn, can lead to increased efficiency, reduced operator fatigue, and a safer working environment.

Customizable Interior Configurations for Specific Needs

Finally, a port manager can enhance the functionality and adaptability of modular control and inspection booths by customizing their interior configurations to meet specific needs. This flexibility allows for efficient use of space and resources while ensuring the booth can cater to various tasks. Here are the key steps to achieve customizable interior configurations:

- Assess Operational Requirements: Start by understanding the specific tasks and functions the booth needs to support. This could include security checks, cargo inspections, documentation, and communication with personnel on the ground.

- Task Zones: Create designated task zones within the booth. For instance, one area may be dedicated to document verification, another for security monitoring, and a third for communication equipment. Clearly define and organize these zones to streamline workflow.

- Flexible Workstations: Implement workstations that can be easily reconfigured. For instance, desks can be designed with adjustable heights to allow operators to alternate between sitting and standing, reducing fatigue during long shifts.

- Equipment Integration: Ensure that the booth is designed to integrate various pieces of equipment seamlessly. This might include monitors, communication devices, inspection tools, and surveillance systems. Equipment racks can be customized to house these devices securely and conveniently.

- Ergonomic Considerations: Customize the interior layout with ergonomics in mind. Place equipment and furnishings in a way that minimizes operator strain and maximizes comfort. Consider factors such as the height and angle of monitors, keyboard placement, and chair ergonomics.

- Storage Solutions: Include versatile storage solutions for equipment, tools, and supplies. Customize shelving, drawers, and cabinets to fit the specific items that operators need to access.

- Accessibility Features: Design the booth accessible to all operators, including those with disabilities. This may involve implementing ramps, wide doorways, and adjustable workstations to accommodate different needs.

- Consult with Operators: Engage with the operators and seek their input regarding the interior configurations. They can provide valuable insights into their needs, workflows, and preferences.

By customizing the interior configurations of modular control and inspection booths to specific needs, a port manager can create a versatile and adaptable workspace that optimizes workflow, enhances operator comfort, and ensures efficient use of resources. This customization is vital for achieving the booth’s intended functions while maintaining flexibility for future requirements.

Choose the Right Modular Control and Inspection Booth Solution with Guardian Booth

Guardian Booth is your trusted partner in selecting the perfect modular control and inspection booth solution for shipping ports.

Our experts assess your unique requirements, space limitations, and budget constraints, guiding you to the optimal solution with suitable security, safety features, and customization options to meet your port management needs.

Here’s how you can use Guardian Booth to benefit your modular control and inspection booth needs:

Assessing Shipping Port Requirements and Space Constraints

Assessing shipping port requirements and space constraints is a fundamental task for a port manager. It is crucial for efficient and safe port operations. Here’s why it’s important and how a port manager can accomplish this assessment:

Importance Of Conducting A Shipping Port Assessment

- Optimizing Space Utilization: A shipping port’s space is valuable, and efficient utilization is critical. By understanding the requirements and constraints, a port manager can ensure that the available space is used effectively, minimizing congestion and bottlenecks.

- Safety and Security: Proper space management is essential for safety and security. Assessing requirements helps establish secure zones and access control, reducing the risk of unauthorized entry and potential security breaches.

- Efficient Operations: Understanding requirements allows for a more streamlined cargo flow, vessels, and personnel flow. It ensures the port operates efficiently, reducing delays and enhancing overall productivity.

- Environmental Compliance: Ports often have environmental constraints due to nearby ecosystems or regulations. Assessing these constraints ensures that port activities do not harm the environment or violate regulations.

How to Accomplish the Assessment

As a starting point for the assessment, collaborate with port stakeholders, including shipping companies, customs authorities, security agencies, and local communities. These discussions provide valuable insights into their needs, concerns, and requirements.

Then, after familiarizing yourself with national and international regulations, industry standards, and safety requirements, physically inspect the port and its surroundings. Evaluate existing infrastructure, storage facilities, vehicle access points, and waterways. Note any physical constraints or opportunities for expansion.

Develop scenarios for various port operations, considering different requirements. This involves simulating the movement of vessels, cargo, and personnel to understand how different configurations impact efficiency.

By systematically assessing shipping port requirements and space constraints, a port manager can make informed decisions about the allocation of resources, infrastructure development, and security measures. This ensures that the port operates efficiently and contributes to safety, security, and environmental responsibility. It is a dynamic process that should be ongoing to accommodate the evolving needs of the port and its stakeholders.

Evaluating Security and Safety Features

Guardian Booth’s security guard booths offer a comprehensive set of safety features that are important for ensuring superior protection and comfort for both personnel and property. Here’s a list of features to consider for your shipping port:

- 360-Degree Vantage Point: The stationary or portable guard booths provide a 360-degree vantage point, allowing guards to monitor the entire facility. This is vital for a port manager as it enhances situational awareness, enabling security personnel to respond quickly to any security or safety concerns in the vast port area.

- Mirrored and Tinted Windows: The mirrored and tinted windows on all sides of the prefab guard booth are essential for security. They allow guards to observe their surroundings without being easily detected by potential threats. This feature is crucial for covert monitoring and early threat detection in a port setting.

- Shatter-Resistant Windows: Upgrading to shatter-resistant windows provides additional protection in worst-case scenarios. This feature helps safeguard guards against potential attacks and ensures the booth remains secure even in high-risk situations, a key concern in port security.

- Weatherproof and Insulated Construction: The two layers of durable aluminum and PPGI panels filled with weather-resistant insulation ensure the guard booth is comfortable and safe in all weather conditions. Port yard managers can rest assured that security personnel will remain focused on their tasks, even during adverse weather conditions, reducing distractions and downtime.

- Climate Control: Including built-in air conditioning and baseboard heaters in the guard booths ensures maximum comfort for personnel working long hours. Maintaining a comfortable working environment is essential, especially in extreme climates, and it can contribute to the effectiveness of security and safety measures.

- Restroom Facilities: The built-in restroom facilities reduce the need for security personnel to leave the guard booth for breaks. This not only improves their comfort but also minimizes the risk associated with leaving the booth unattended.

- Swiveling LED Spotlights: The swiveling LED spotlights mounted on the outside of the guard booth enhance property illumination, which is critical for port security. Well-lit areas deter trespassers, improve surveillance, and help secure inventory and assets, which is essential in a port setting with valuable cargo.

- Mobility: Portable security booths offer extra mobility, allowing port managers to deploy security resources where they are needed most. This feature enables flexibility in responding to changing security and safety needs, particularly in a dynamic port environment.

Our security guard booths provide a range of customizable features that cater to the specific needs of a port yard manager. These features balance superior protection and ultimate comfort, ensuring security personnel can effectively safeguard the port’s assets and personnel.

Considering Customization Options and Budgetary Factors

When selecting a modular control and inspection booth solution, a port manager must balance the port’s specific needs, available resources, and financial considerations.

Guardian Booth is dedicated to simplifying this pivotal decision-making process by offering tailored customization options that address your unique requirements while staying within budget constraints. Our goal is to deliver a cost-effective yet highly efficient solution for port management that enhances your operational value.

To ensure accessibility and budget-friendliness, we provide flexible payment plans that accommodate your financial situation. We understand the importance of balancing your budget while obtaining your port’s security and safety measures.

Our comprehensive warranty package reflects our commitment to your peace of mind. This package offers long-term reliability, ensuring our solutions are built to last and perform consistently.

At Guardian Booth, we are dedicated to delivering exceptional modular control and inspection booths and a holistic, value-driven experience that caters to your distinct needs. This includes a focus on the following customization options and budgetary factors that should be considered by a port manager when choosing a control or inspection booth:

Customization Options

- Layout Configuration: Customize the interior layout to accommodate specific tasks, equipment, and workflow requirements. This ensures maximum efficiency.

- Security Features: Tailor the booth’s security features, such as access control systems, surveillance equipment, and communication systems, to align with your security needs.

- Climate Control: Opt for climate control systems that match the local climate, ensuring a comfortable working environment for personnel.

- Environmental Compliance: Customize features for environmental safety and compliance with regulations, such as spill containment systems.

- Accessibility: Ensure the booth’s design meets accessibility requirements, making it usable for all personnel.

Budgetary Factors

- Initial Cost: Consider the upfront cost of the booth, including the purchase price and any necessary infrastructure modifications.

- Operating Costs: Assess ongoing operating expenses, such as energy consumption, maintenance, and personnel costs.

- Long-Term Cost-Effectiveness: Weigh the lifetime cost of the booth against the benefits it provides in terms of enhanced security, safety, and operational efficiency.

- Financing Options: Explore payment and financing options to align with your budgetary constraints.

- Warranty and Reliability: Examine the warranty package to ensure long-term reliability and potential cost savings related to maintenance and repairs.

By carefully evaluating these customization options and budgetary factors, a port manager can make an informed decision when selecting a control or inspection booth solution that meets the port’s specific requirements while staying within budgetary constraints. Guardian Booth is committed to assisting in this process to provide a tailored and cost-effective solution for your port management needs.

Choose Guardian Booth as your Modular Control / Inspection Booths Supplier

When it comes to selecting a supplier for modular control and inspection booths, Guardian Booth stands out as the go-to choice for reliability and excellence. In a market crowded with options, we distinguish ourselves by offering products that consistently surpass industry standards. Our commitment to quality and craftsmanship ensures that each booth is built to last, withstand rigorous operational demands, and provide uncompromising reliability.

Guardian Booth has earned a reputation as a trusted supplier through years of delivering cutting-edge modular booth solutions that meet and exceed customer expectations. Our dedication to customer satisfaction is reflected in our ability to tailor each booth to specific needs, whether for shipping ports, industrial facilities, or other critical environments.

With Guardian Booth, you’re not just purchasing a modular control and inspection booth; you’re investing in a dependable solution that enhances your operations’ efficiency, security, and overall performance.

Choose us as your supplier, and experience peace of mind in the reliability and excellence of our products.

Upgrade your control booth today for streamlined operations and enhanced security. Contact us to elevate your control center.

Recent Blogs

Creating Portable Break Areas for Agriculture Staff with Prefab Booths

In the demanding world of agriculture, staff members often face challenges finding suitabl…

Utilizing Portable Booths as Make-Shift Shelters in Agriculture Fields

In the vast expanse of agriculture fields, specific situations necessitate the establishme…

How to Use Portable Booths for Storage on Agriculture Farms

On agriculture farms, adequate storage is crucial for maintaining equipment, tools, suppli…